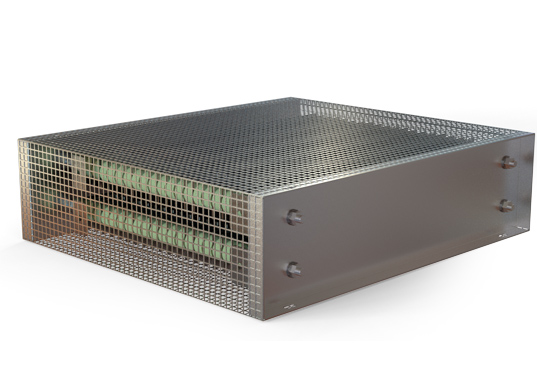

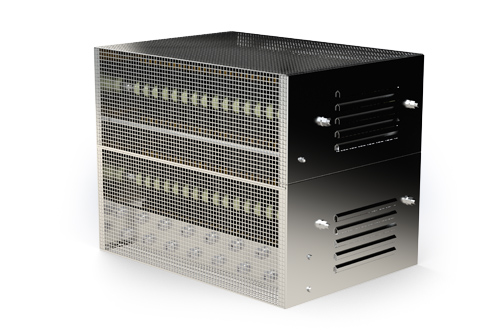

Starting resistors for overhead cranes, mining and construction conveyors, DC resistors, automatic resistance starters

Starting resistor is used for starting and adjusting the rotation of induction motors and other high power electrical machines.

Frame Starting resistor is connected to three phases of motor rotor winding, using U, V and W terminals. The start up consists in activating individual resistance stage of the resistor. The use of active resistance in the rotor circuit reduces the motor starting current to a value being only about twice as high as the rated current and increases the starting torque thanks to which such motor can be started under load.

Formerly, starting resistors were used practically in every electric drive with a wound rotor motor. They could be found in traction vehicles, where they were responsible for the drive of electric locomotives, trams and trolleybuses. In the crane industry, starting resistors were responsible for the drive of overhead cranes, cranes or even ski lifts. The heavy industry sector used them, for example, as starting resistors for mining conveyors transporting tons of coal and for rock crushers used in cement factories and steel mills.

Currently, starting resistors for wound rotor motors are no longer practically used in new drives (with few exceptions) because the design solutions of drives have changed. They are replaced by drives using frequency converters – inverters. However, starting resistors are still produced as replacements for old cast iron and FeCrAl constructions, on newer simple steel grid and ribbon-like resistance elements.

Nowadays, starting resistors are mainly used in construction, mining and maritime industries.

The production of starting resistors in the SIMPAX company is carried out in accordance with the ISO 9001:2015 quality system. For the production of resistors, we use the latest technologies, proprietary construction solutions, modern resistance elements and materials tested in the railway industry. Our starting resistors meet the highest requirements in terms of quality, safety and durability. These reliable units are characterized by failure-free operation over a long period of time.

SIMPAX manufactures starting resistors for every application, power (from a few Watts to a MW) and load cycle.

Note: Based on many years of experience and advanced 3D modeling, we can custom design a non-standard braking resistor, requiring unusual resistance elements and power [see SPECIAL DESIGN RESISTORS], including replacements units for old type braking resistors.

We invite you to familiarize yourself with the offer of starting resistors manufactured by SIMPAX:

- starting resistors for overhead cranes

- starting resistors for mining conveyors

- start-up DC resistors

- automatic resistance starters

Parameters of starting resistor

| Resistor operating current [A] | In accordance with the starting current which results from the motor impeller parameters |

| Start-up time: | In accordance with machine start-up characteristics |

| Type of operation: | Pulse operation (only for start-up), cycle operation [%] for speed regulation resistors |

| Resistance: | Specify total phase resistance and the resistance of individual start up stages |

| Start-up stages: | From 2 to 6 as standard, in accordance with machine start-up characteristics |

| Insulation voltage: | ≤ 1kV, or ≥ 1kV |

| Type of cooling: | Natural, forces by fans, or oil cooling |